Machinery Repair

Industrial Parts Specialties, LLC has the experience and resources to provide turnkey service for your critical application multi-stage pumps and a wide variety of rotating machinery. Our diversified capabilities allow us to give you a repair every bit as good as you would get at an OEM shop with a much quicker turnaround and at a cost that provides a much higher value to the end user. Several of our staff have come to us with prior OEM shop experience, so they have had the training as well as experience of working in that environment and bring that to IPS. We take that knowledge and combine it with our value added service concept to deliver a first class repair faster, at a lower cost and every bit as good as what you would get if you send it to a OEM service shop. We pride ourselves on providing a level of service that is unattainable by our competition.

Services Available

COMPREHENSIVE DISASSEMBLY AND INSPECTIONS

PRECISION MEASUREMENT OF ALL FITS

HARDNESS CHECKS OF ALL WEAR PARTS

DETAILED SCOPE OF WORK WITH FIRM QUOTATION

REPAIR REPORT PRODUCED WITHIN 5 WORKING

DAYS AFTER COMPLETION OF JOB

PUSH/PULL CAPABILITY ON SELECTED TYPES OF MACHINERY

STATE OF THE ART BALANCING CAPABILITIES

ON SITE PMI MATERIAL VERIFICATION

Machinery Repair

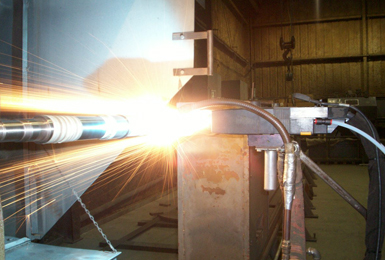

Tools | Facilities

CONTACT FORM